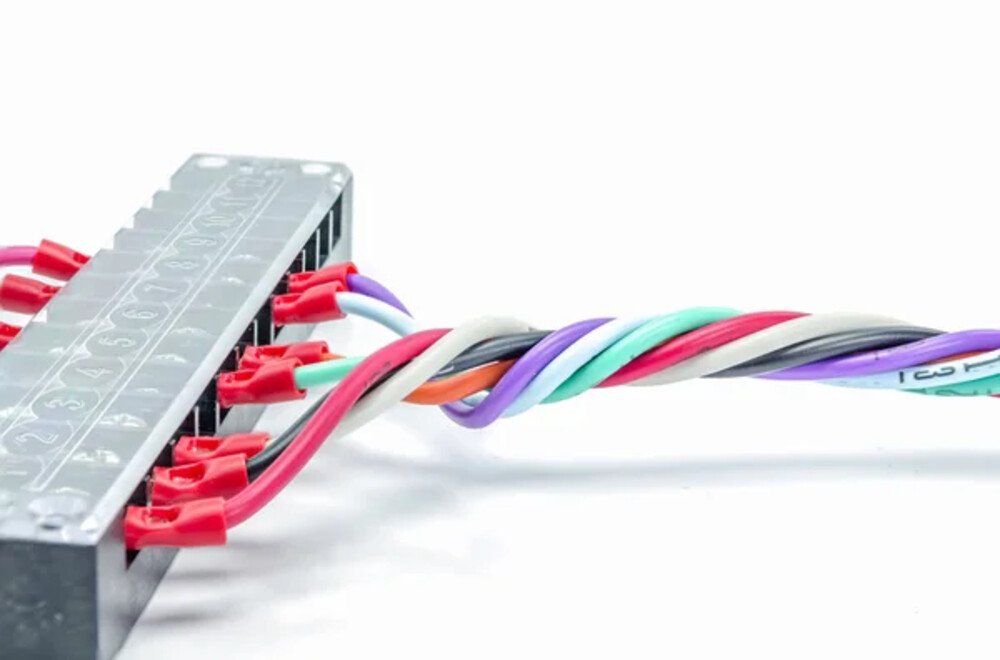

Proper electrical wire connector terminal installation requires good mechanical strength and electrical conductivity. Also, proper installation is critical to any electrical project.

Electrical wire connectors terminals are used to securely join two electrical circuits, ensuring a reliable and safe connection.

However, installing these connectors improperly can result in hazardous circumstances, like fires or electric shock. This is why electricians use proper safety gear and measures. They also adhere to the installation instructions.

How to Ensure Proper Electrical Wire Connector Terminals Installation

With proper installation of electric wire connector terminals, expect an effective and safe electrical system. Here are a few tips on how to can ensure the appropriate installation of these connectors:

- Choose the right electrical wire connector types for the job.

- Prepare proper wires for installation.

- Connect the wires to the terminals correctly.

- Ensure that the connection is secure.

Furthermore, consider the wire type and its application when selecting a connector. Remember, a specific connector type works with a certain kind of wire. After the selection process, prepare the wire appropriately to ensure it is suitable for the installation. This step involves:

- Stripping the insulation from wire ends to expose conductors.

- Soldering or crimping the connector to the exposed wires.

Getting Familiar with the Type of Connector

Understanding the type of connector you use is critical to ensure the proper connection for a specific purpose.

Connectors come in different types with a variety of applications, from household wiring to commercial and industrial use.

When familiarizing yourself with the type of connector, you can consider the following ideas:

- Different connectors come in varying sizes, materials, shapes, and connection types.

- Understanding these properties help prevent any potential issues with component integrations.

- It is essential to consider the environment in which the connectors will be used, including various connection types and materials.

- Familiarity with different types of connectors helps reduce the cost and time associated with testing and prototyping.

How to Test the Connections for Electrical Current or Continuity

As you test the connections for electrical current or continuity, you can ensure the current flows where required. This also ensures that the wiring is safe and intact.

To do this, you need to:

- Use a multimeter, which measures the circuit’s continuity and detects any problems with the current.

- Make sure the wiring is properly grounded.

- Ensure that the insulation is intact.

How to Install Electric Wire Connectors Terminals Properly

Below are simple steps on how to make proper and safe wire connections:

- Check the wire nuts packaging label to ensure a safe wire combination.

- Strip the wire ends using a wire-stripping tool.

- Arrange the wires parallel to each other, ensuring the ends are aligned with them.

- Put the wire nut connector over the wires.

- Twist the connector until the insulated wires start to twist.

- Secure them by tugging on each wire.

- Extend the ends of the stranded wires by 1/8 inch.

- Install the wire nut connector.

- Bend a ¾ inch length of the stripped wire with the point of the wire strippers.

- Close the loop around the screw by wrapping the wire clockwise.

- Tighten the screw.

- Cut off twisted, bent, or nicked ends.

- Strip the wires to the length displayed on the stripping gauge.

- Turn the terminal screw to loosen it by turning it counterclockwise until the clamp opens.

- Hold each wire in every hole while tightening the screw.

- Tug on the wires after ensuring a secure connection.

With attention to detail, you can rest assured that the wiring job is properly and securely done.

Recommended Posts: